Description

Key Features :

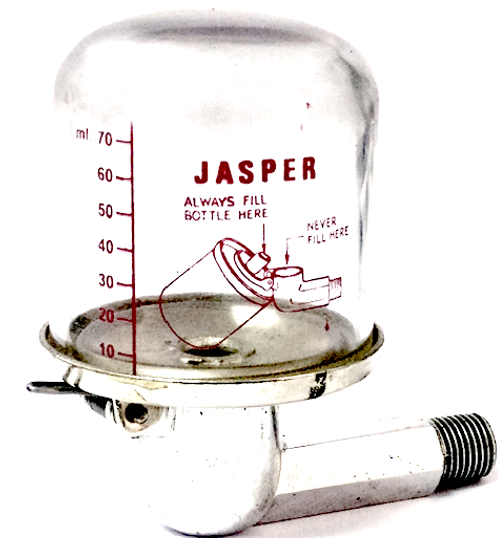

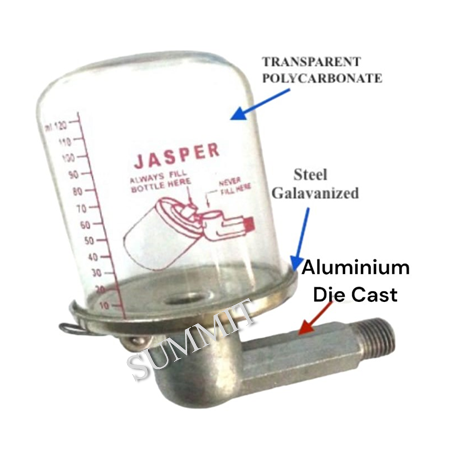

- Sizes : Capacity – 70 ML and 120 ML , Threads – 1/4 BSP , 3/8 BSP , 1/4 NPT etc.

- Made of Aluminium Casting.

- The transparent cup is made of Polycarbonate which is Breakage Resistant. The poly carbonate cup has marking for Liquid level and usage instruction printed on it.

- This is useful to maintain oil level in Machines. Used in various industries – like – Paper, Oil Exploration, Paint, Pharma, Steel, Aluminium, Printing etc.

Keeping these oilers properly filled, along with ongoing inspection and maintenance, significantly extends bearing life.

Making constant-level oiler maintenance a consistent part of your plant service procedures will significantly extend the service life of all your motor stock, and can virtually eliminate unexpected bearing failure due to lack of lubrication.

We are the largest manufacturer of Constant Level Oiler in World with production capacity of over 100,000 pcs monthly.

SUMMIT – JASPER – Constant Level Oiler is exported to over 50 countries globally, having running annual contracts with some of top Fortune 500 companies.

Made In India Since – 1962

Reviews

There are no reviews yet.